Equipment and Technology

To ensure high quality and large capacity of our products, we use modern and automated machinery.

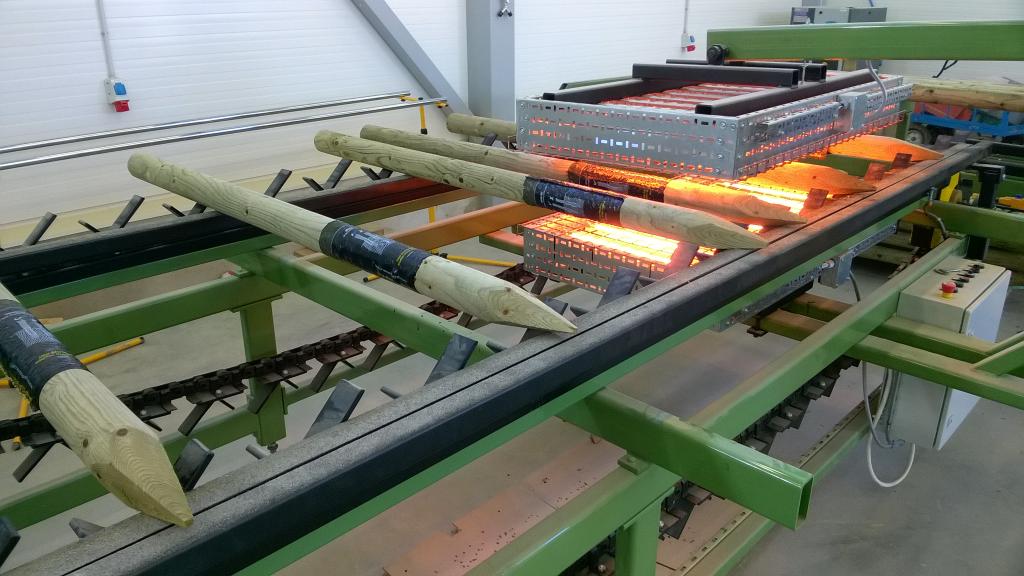

MACHINE ROUNDED TIMBER PRODUCTION PROCESS

1. SORTING RAW LOGS

On sorting line the logs are sorted by length and species into different diameter log pockets and placed to sorted logs storage area.

2. MACHINING

Based on the dimensions of the logs, the raw logs are cross-cut into lengths, chamfered, pointed and split.

3. POST-PROCESSING

Semifinished products are directed to post-production (drilling, jointing, mortising, etc.), and products that are to be pressure treated right after machining head to treatment tank and products that require pre-drying go to the kiln dryer or to the stock if the weather is suitable for drying outside.